Nine design requirements for automotive connectors

1、Stable and reliable connector contact materials

2、Positive force stability

3、The voltage and current of the connector connected circuit are stable

4、The temperature must be within the specified range, including the surrounding temperature and its own temperature rise

5、Better robustness, automotive connectors must be able to work reliably under harsh conditions

6、Must be the same connector as used in computers for high-speed, long-distance communications

7、Connector insertion force: 20.5kg or less

8、Connector retention force: 2.5kg or more

9、Temperature adaptability: -40~120℃

When a car is driving, all its parts must work and cooperate closely with each other. In the cooperation of various parts in the car, the car connector plays a very important role.

Whether it is a traditional car or a new energy car, in the automotive industry, connectors have always been valued by engineers. In some traffic accident analyses, people found that many traffic accidents were caused by connector failure.

From the purpose of using the automotive connector, in order to ensure better driving of the car, we can divide the reliability of the connector into the sealing of the connector during use and the anti-spark performance of the car during driving.

In addition, during the driving of the car, the connector can also show shielding performance and temperature control performance.

Generally, when discussing the sealing performance of automotive connectors, it is not only the sealing performance against water in the car that is considered. In this field, the current internationally popular management standard is IP67, and this standard is also the highest level in the automotive sealing industry.

Although the requirements for waterproofing are different in different parts of the car, many car manufacturers will choose IP67 to ensure the sealing performance of their car connectors.

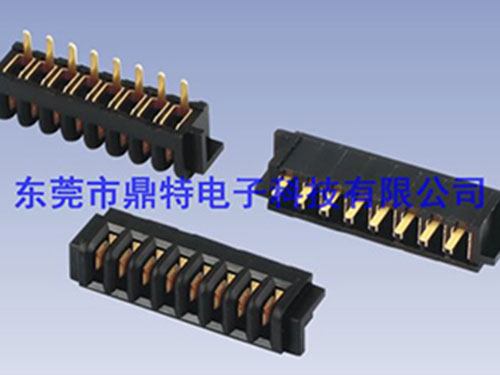

Automotive Connectors

When a car is driving, power is a very important energy source, which is not only related to the normal operation of the engine, but also often involves the use of power when people are driving. Therefore, in the power supply system of the car, the car connector has different divisions, and there are certain sealing measures that can be implemented between the male connector and the device, between the male connector and the cable, between the male and female connectors, and between the female connector and the cable.

In order to achieve the sealing performance of automotive connectors, sealing rings are a commonly used tool. This tool can not only achieve the fixing effect between different holes, but also achieve the sealing effect. It can not only ensure the stable operation of automotive equipment, but also ensure the waterproof performance of automotive equipment during work.

Most of the sealing rings are made of silicone rubber, which is made by liquid silicon and solid silicon after certain chemical changes.

Nowadays, when cars are in use, electronic circuit technology is an important aspect of the automotive industry. Not only in driver entertainment, but also in the control system of the car while the driver is driving, electronic circuit technology plays an important role in the stable operation of the car.

In order to ensure the stable operation of electronic circuit technology, people now use a lot of shielding technologies in automobile production. These shielding technologies not only play a protective role in the electronic circuits of automobiles, but also play an anti-interference and anti-radiation role in automobile components.

In addition, they can also protect the stable operation of automobile connectors. These shielding technologies can be divided into two types in automobiles: internal shielding and external shielding.

When using an external shield to protect an automotive connector, two identical shield shells are usually assembled together to form a shield layer, and the length of the shield layer can cover the entire length of the connector. The shield layer shell must also have sufficient locking structure to ensure the reliable installation of the shield layer.

In addition, the shielding material used must not only be electroplated, but also treated to prevent chemical corrosion.

(PS: The article is transferred from the WeChat public account of the Connector Information Platform. If there is any infringement, please contact the website administrator to delete it.)