What are the wide applications of pin headers?

Pin headers are widely used in PCB board connections and are known as universal connectors. They are usually paired with female headers, wire terminals and other connectors. With the competition in the pin header connector market, some manufacturers are now reducing costs by improving electroplating (imitation gold) and materials (green steel, alloy, etc.), but this also reduces the product's usability and lifespan.

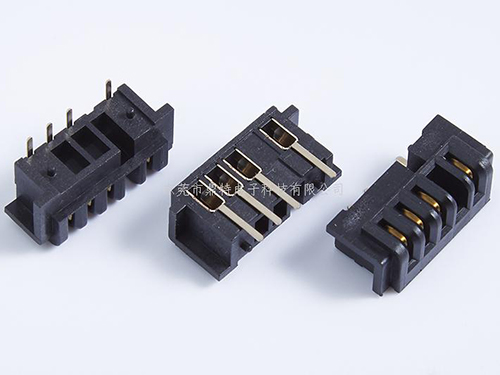

Pin header, a type of connector, English name: Pin Header.

This type of connector is widely used in PCB circuit boards in electronics, electrical appliances, and instruments. Its function is to act as a bridge between blocked or isolated circuits within the circuit, and to take on the task of current or signal transmission.

It is usually used with a female header to form a board-to-board connection, or used with an electronic wiring harness terminal to form a board-to-wire connection. It can also be used independently for board-to-board connection.

Since different products require different specifications, there are also many types and specifications of pin headers, which are classified according to the pin header connector standards of the electronics industry:

According to the pitch, it can be roughly divided into five categories: 2.54mm, 2.00mm, 1.27mm, 1.00mm, and 0.8mm. According to the number of rows, there are single-row needles, double-row needles, triple-row needles, etc.; according to the packaging usage, there are SMT (horizontal/vertical), DIP (straight/bent plug-in), etc.; according to the installation method: 180° is represented by S, 90° is represented by W, and SMT is represented by T.

Number of rows: single row, double row, triple row, quad row, up to quad row. Number of pins: 02 to 80 Pins: straight pin, bent pin, SMT; pin size. Dimensions: overall dimensions length, width, thickness, row spacing. Pitch: 0.8, 1.0, 1.27, 2.0, 2.54 pitch. Material: refers to the material and surface treatment of the contact, the material of the insulator. Packaging: blister packing, roll bag, bulk. Material: Pin material: brass or phosphor bronze; insulator material: plastic UL94V-0. Surface treatment: gold plating 0.8u, tin plating, nickel plating. Processing technology: The main process of pin processing is: first use brass (or phosphor bronze) to process the pins as required, and first nickel plate and then gold plate as required, then use the mold to process the insulator part, and finally insert the pins into the insulator according to the size requirements on special equipment. Remarks: There are many factors that affect the price, usually the biggest influence is gold plating, pin length, etc. Pin header parameter example Features: single row and double row, straight pin and curved pin, pin spacing of 2.54mm and 3.96mm, various pin lengths. Pin header applications ●Data processing ●Computer ●Program control equipment ●Electronic measuring equipment ●Automatic control ●Automation ●Communication The cross section of the rectangular pin is 0.8×1.6mm, and the load current is 7.5A. The socket has at least two independent springs and four contact points, and the socket structure can prevent mis-insertion. The cross section of the 254/I series square pin is 0.64×0.64mm. The above two types of pins are designed with blunt corners and can be used in the field of high-frequency technology. The pinhole contact part is gold-plated, which is corrosion-resistant, has low contact resistance and high reliability.