Electronic connector manufacturing technology

There are many types of electronic connectors, but the manufacturing process is basically the same. Generally speaking, it can be divided into four stages:Stamping,Plating,Molding,Assembly

1、Stamping:

The manufacturing process of electronic connectors generally starts with stamping pins. Electronic connectors (pins, terminals) are stamped from thin metal strips using large high-speed stamping machines.

One end of a large roll of metal strip is fed into the front end of the stamping machine, and the other end passes through the stamping machine hydraulic workbench and is wound into a take-up wheel, which pulls out the metal strip and rolls it up to stamp out the finished product.

2、Plating:

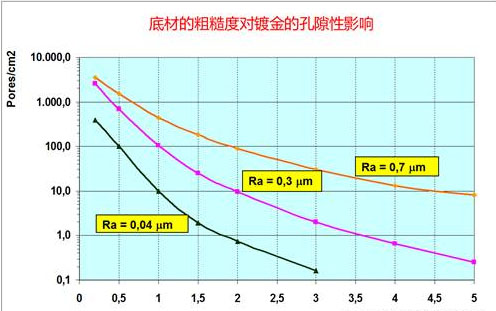

After the terminals and pins are stamped, they should be sent to the electroplating section. At this stage, the electronic contact surface of the connector will be plated with various metal coatings.

The twisting, breaking or deformation of the pins occurs during the process of sending the stamped pins to the electroplating equipment. Through the detection technology described in this article, such quality defects can be easily detected.

However, for most machine vision system suppliers, many quality defects that occur during the electroplating process are still off-limits for inspection systems. Electronic connector manufacturers want inspection systems to detect various inconsistent defects such as small scratches and pinholes on the surface of connector pin plating.

Although these defects are easy to identify for other products (such as aluminum can bottoms or other relatively flat surfaces); due to the irregular and angled surface design of most electronic connectors, it is difficult for visual inspection systems to obtain images sufficient to identify these subtle defects.

Since some types of pins need to be plated with multiple layers of metal, manufacturers also want the inspection system to be able to distinguish between various metal coatings in order to verify whether they are in place and the correct proportions. This is a very difficult task for a visual system using a black and white camera, because the grayscale images of different metal coatings are actually almost the same.

Although the camera of the color vision system can successfully distinguish these different metal coatings, the problem of difficult lighting still exists due to the irregular angles and reflections of the coating surface.

3、Molding:

The plastic housing of the electronic connector is made during the injection molding stage. The usual process is to inject the molten plastic into the metal membrane and then quickly cool it to form. When the molten plastic fails to completely fill the membrane, so-called "short shots" occur, which is a typical defect that needs to be detected during the injection molding stage.

Other defects include filling or partial blockage of the sockets (these sockets must be kept clean and unobstructed to properly connect with the pins during the final assembly). Since the use of backlight can easily identify the missing housing and the blocked sockets, the machine vision system used for quality inspection after the injection molding is completed is relatively simple and easy.

4、Assembly:

The final stage of electronic connector manufacturing is the assembly of the finished product. There are two ways to connect the electroplated pins to the injection molded box seat: single plug-in or combined plug-in. Single plug-in means plugging one pin at a time; combined plug-in is to plug multiple pins into the box seat at the same time.

Regardless of the plug-in method, manufacturers require that all pins be inspected for missing and correct positioning during the assembly stage; another type of routine inspection task is related to the measurement of the spacing on the mating surface of the connector.

Like the stamping stage, the assembly of connectors also poses challenges to the automatic inspection system in terms of inspection speed. Although most assembly lines have a beat of one to two pieces per second, for each connector passing through the camera, the visual system usually needs to complete multiple different inspection items. Therefore, the inspection speed once again becomes an important system performance indicator.

After assembly, the connector's dimensions are orders of magnitude greater than the tolerance allowed for a single pin. This also poses another problem for the visual inspection system. For example, some connector boxes are larger than one foot in size and have hundreds of pins. The detection accuracy of each pin position must be within a few thousandths of an inch. Obviously, it is impossible to complete the inspection of a one-foot-long connector on one image. The visual inspection system can only detect the quality of a limited number of pins in a small field of view at a time.

There are two ways to complete the inspection of the entire connector: use multiple cameras (increasing system costs); or continuously trigger the camera when the connector passes in front of a lens. The visual system stitches the continuously captured single-frame images together to determine whether the quality of the entire connector is qualified. The latter method is the inspection method commonly used by the PPT visual inspection system after the connector is assembled.

The detection of the true position is another requirement for the detection system in connector assembly. This true position refers to the distance between the top of each pin and a specified design reference line. The visual inspection system must make this imaginary reference line on the inspection image to measure the actual position of each pin vertex and determine whether it meets the quality standard.

However, the reference point used to define this reference line is often invisible on the actual connector, or sometimes appears on another plane and cannot be seen at the same time in the same lens. In some cases, the plastic on the connector box must be ground off to determine the position of this reference line. There is indeed a related topic here - detectability design.

Inspectablity

As manufacturers continue to demand improved production efficiency and product quality and reduced production costs, new machine vision systems are increasingly being used. As various vision systems become more common, people are becoming more familiar with the characteristics of such inspection systems and have learned to consider the detectability of product quality when designing new products.

For example, if you want a reference line to detect the actual position, the visibility of this reference line should be considered in the connector design.